History

Iran Radiator Industrial Group with an over 40 years of background and consisting of many factories, is one of the largest and most experienced manufacturing units of the country which is active in the field of producing different types of steel and aluminum radiators, wall-mounted and floor-standing packages, gas, gasoline and hybrid burners, 5 layered pipes, gas and ducted split air conditioners.

Today, the Company has achieved significant growth throughout its history and by improving the quality of products and achieving the title of “National Best Qualified Selected Unit” from ISIRI twice as well as having an active and respectable presence in European reputable international exhibitions which has led us to achieve many international certificates such as France NF, European CE, British BSI,…, this group has been developed vastly.

Innovations

Iran Radiator has been successfully gaining the titles of the largest die-casting unit in ME, the second manufacturer of aluminum radiator in the world, the largest producer of burner in ME and the fourth in the world as well as the largest manufacturer of towel radiator in ME.

The products made by Iran Radiator Industrial Group have been honorably exported to over 30 countries including industrial developed ones such as Italy, Spain, Germany, France, Russia, etc. .Also, this group has been winning the prestigious “Exporter of the Year” award (from the Ministry of Trade) for three times and in 2016, it turned to the largest exporter of wall-mounted radiator packages to the Europe continent.

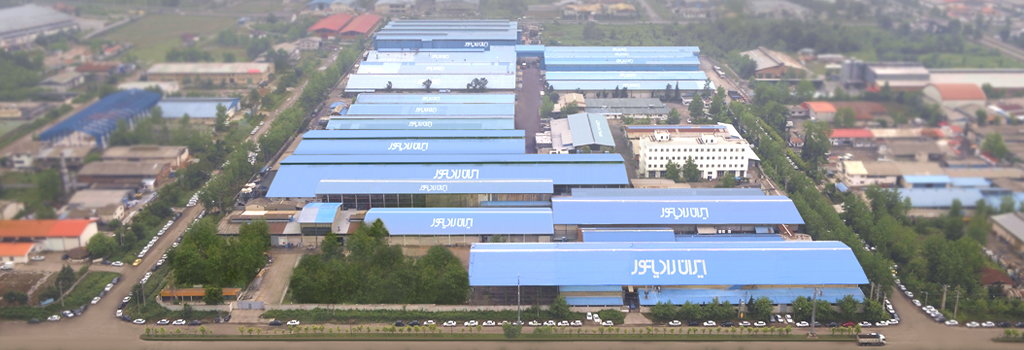

Before Iran Radiator’s establishment, radiators were not manufactured in Iran and were imported from abroad due to the lack of die-casting advanced systems in Iran. After about one year of research and study about manufacturing aluminum radiators inside the country, Iran Radiator started working in March 1980 in east of Tehran. For the first time in Iran, the installation and running of massive 1200 ton die-casting presses accomplished without any help from abroad. Finally, in 1987, due to a shortage of space, production increase and the impossibility of more development in Tehran, we moved our production site with all equipment and machineries to Rasht Industrial City.

After meeting the country’s need for radiators, in 1992, Mashal Kar Rey Company was established to provide the needed burners for heating systems in industrial and constructional sections. Now, this company also supplies dozens types of gas burners, gasoline burners and hybrid burners by maximum 5,000,000 kcal/hr in order to meet the needs of these sections as well.

Since 2005, wall- mounted and floor-standing radiator packages were manufactured and presented in various models through cooperation with European reputable companies in order to transfer the up-to-date and modern technology of Europe to Iran.

Using the best European parts and applying the most advanced research package laboratory in Iran by the Italian MicroPlan Company, led us to successfully gain the National Standard badge from ISIRI in the least time and as the first Company in Iran, receive the Technical Certificate from Road, Housing and Urban Development Research Center for the designed package.

Since 1998, Iran Radiator’s 5 layered composite pipes entered the market by applying the western European most premium raw materials as well as the high-tech relevant equipment and joints (Press-fitting and threaded). In a short time, the company succeeded to achieve the National Standard badge from ISIRI and as the first Company in Iran, receive the Technical Certificate from Road, Housing and Urban Development Research Center for the designed package.

Now, after decades of activity in the facilities industry, panel radiators have been professionally produced and launched in the market. We hope that like our other products, this product makes us honored in the eyes of our dear customers and compatriots as well.

Perhaps it is unimaginable for everyone that a small factory which started working with just 30 employees, 3500 m²area and two die-casting machines, could successfully create about 1500 direct job opportunities and 10 thousand indirect ones in 2014 in spite of the economy difficulties by thirty die-casting machines, dozens of saloons for mold-making, casting, production and assembling different products as well as tens of hectares for production space. It is worth mentioning that it is not easy to compete with industrial developed countries and even export to European ones while full supplying of domestic needs.

Regarding the production quality, it should be noted that during the process of manufacturing different products, quality control unit with a high sensitivity and accuracy has a constant supervision on the process and the product is tested in different stages. For example, radiators are packed after three stages of undergoing pressure tests and two stages of painting tests or all types of burners are first lit and after flame testing, are packed. Also, wall-mounted packages boilers are tested at the end of the production line for all expecting items from a perfect package.

For providing raw materials needed for products’ manufacturing, in order to develop economic prosperity and create employment, we have tried to prioritize Iranian goods and in case of lack of Iranian high quality materials, we provide raw materials directly and with no dealers from European (Germany, Italy, France,…) reputable sources. As a result of all these efforts, the quality of products have had a significant dynamic growth which has changed the guarantee validity from 5 years into 10 years as well as guarantee validity increase for packages from 18 months to 24 months in 2011.

According to the high share of Iran Radiator Industrial Group in the markets of boilers, radiators, burners, multilayered composite pipes alongside the country’s current policies in the field of energy efficiency and the CSR towards the country’s national capital and environmental resources, this Company has been always keeping up with research and development and using the world modern technologies. In this regard, the contracts with European reputable companies such as German Dreisler Company as well as setting up high-tech and unique laboratories in Iran and Middle East region especially considering the price of radiator and 5 layered composite pipes should be mentioned. Also, by after-sales services different from the common guarantee conditions, such as replacement of radiators which break negligently while installing, our least expectation from all those who care about this country is making this slogan come true in practice: “Iranians, consume high-quality Iranian product” and together , creating a dynamic employment for our compatriots.